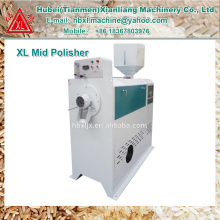

100T/D high qualtiy rice plant parboiled rice machine

Basic Info

Model No.: XL-100

Product Description

100T/D high qualtiy rice plant parboiled rice machine

n modern rice mills, many adjustments (e.g. rubber roll clearance, separator bed inclination, feed rates) are automated for maximum efficiency and ease of operation. The whitener-polishers are provided with gauges that sense the current load on the motor drives which gives an indication of the operating pressure on the grain. This provides a more objective means of setting milling pressures on the grain.

Objective of commercial milling

A commercial rice miller will have following objectives:

- produce edible rice that appeals to the customer- i.e. rice that is sufficiently milled and free of husks, stones, and other non-grain materials

- maximize the total milled rice recovery out of paddy minimize grain breakage

Flow diagram of a modern rice mill

The flow diagram below represents the configuration and flow in a typical modern rice mill.

1 - paddy is dumped in the intake pit feeding the pre-cleaner

2 - pre-cleaned paddy moves to the rubber roll husker:

3 - mixture of brown rice and unhusked paddy moves to the separator

4 - unhusked paddy is separated and returned to the rubber roll husker

5 – brown rice moves to the destoner

6 - de-stoned, brown rice moves to the 1st stage (abrasive) whitener

7 - partially milled rice moves to the 2nd stage (friction) whitener

8 – milled rice moves to the sifter

9a - (for simple rice mill) ungraded, milled rice moves to bagging station

9b – (for more sophisticated mill) milled rice moves to the polisher1

10 - Polished rice, will move to length grader

11 - Head rice moves to head rice bin

12 – Brokens moves to brokens bin

13 – Pre-selected amount of head rice and brokens move to blending station

14 – Custom-made blend of head rice and brokens moves to bagging station

15 – Bagged Rice moves to the market

A – straw, chaff and empty grains are removed

B - husk removed by the aspirator

C – small stones, mudd balls etc. removed by de-stoner

D - Coarse (from 1st whitener) and fine (from 2nd whitener) bran removed from the rice grainduring the whitening process

E - Small brokens/brewer’s rice removed by the sifter

Examples for outputs from the different stages

Clean paddy after pre-cleaning

Paddy grain after precleaning. Poor quality grain is evident from its darker color. These are immature kernels or half filled grains that are not removed in the precleaner. The presence of poor quality grain lowers the total milling recovery.

Brown rice at the rubber roller husker

Mixture of paddy grain and brown rice coming out of the rubber roll husker. With uniform size paddy, about 90% of the paddy should be husked after the first pass. This mixture goes through a paddy separator, after which the paddy is returned to the husker,and the brown rice goes to a de-stoner.

Milled rice after polisher

Milled rice after the 2nd stage friction polisher. Small broken grains are still evident. This product goes to a sifter to remove the small broken grains.

Note: Most mills have several polishing stages for gentle milling. In those mills there is undermilled rice after the 1st stage friction whitener. Not all the bran layers are fully stripped. In times of rice shortage, production of undermilled rice is promoted because of the higher milling recovery.

Brewers rice from the sifter

Brewer’s rice or small broken grains removed by the screen sifter.

Xianliang Brand complete set rice milling equipment ranked first in the same industry of our country and the complete set rice milling equipment with daily output of 20~400 t white rice has won the third prize of National Science and Technology Progress; the processing technology and equipment for clean rice have won a national invention patent; the technologies of husking in stage, twice husk sucking, twice stoning, brown rice finishing, brown rice sorting and light whitening through multiple passages etc. represent the current advanced rice milling technologies and equipment in our country.

The specialized sale team and perfect service system after sale can provide the one-stop service for users in technical consultation, process design, installation and commissioning, technical training. Wufeng has won the users acceptance and good social prestige by aborative design, consummate manufacture, careful construction and all-round management.

Major Equipment

1. Drum sieve cleaner SCY80 1 SET

2. Vibratory cleaner TQLZ125 1 SET

3. De-stoner TQSX125 1 SET

4. Pneumatic paddy husker TH10S 1 SET

5. Double body Paddy Separator PS46 1 SET

6. Abrasive rice whitener TWVA40 2 SETS

7. Abrasive rice whitener TWVF21 1 SET

8. White rice plan-sifter MJP120*4 2 SETS

9. Mist polisher SP160B 2 SETS

10.Length grader LG71*2 1 SET

11.Color sorter with compressor XL192CCD 1 SET

12.Bucket eleavtor DTG26/13 1 SET

13.Bucket eleavtor DTG26/13 16 SETS

Air Exhaust part

Electric control part

Affiliated equipment part

Packing part

Others

Flow diagram of a modern rice mill

The flow diagram below represents the configuration and flow in a typical modern rice mill.

1 - paddy is dumped in the intake pit feeding the pre-cleaner

2 - pre-cleaned paddy moves to the rubber roll husker:

3 - mixture of brown rice and unhusked paddy moves to the separator

4 - unhusked paddy is separated and returned to the rubber roll husker

5 – brown rice moves to the destoner

6 - de-stoned, brown rice moves to the 1st stage (abrasive) whitener

7 - partially milled rice moves to the 2nd stage (friction) whitener

8 – milled rice moves to the sifter

9a - (for simple rice mill) ungraded, milled rice moves to bagging station

9b – (for more sophisticated mill) milled rice moves to the polisher1

10 - Polished rice, will move to length grader

11 - Head rice moves to head rice bin

12 – Brokens moves to brokens bin

13 – Pre-selected amount of head rice and brokens move to blending station

14 – Custom-made blend of head rice and brokens moves to bagging station

15 – Bagged Rice moves to the market

A – straw, chaff and empty grains are removed

B - husk removed by the aspirator

C – small stones, mudd balls etc. removed by de-stoner

D - Coarse (from 1st whitener) and fine (from 2nd whitener) bran removed from the rice grainduring the whitening process

E - Small brokens/brewer’s rice removed by the sifter

We have exported rice processing machinery to many countries these include:

Halal Ja Industrials Ltd, Raymos Guanah Farms, RAF RICE AND AGRO. COMPANY in Nigeria

Tecco Ltd in Tanzania

Dok Alternatibo Herbal Products in the Philippines

Om International Traders in India

Weilai Machinery in India

MRS W S K ARIYARATNE DE SILVA Sri Lanka

Emdad Machine Abzar co ltd Iran

Bano Eurotech Ltd UK

In Benin, Tanzania, Senegal, Philippine, Nigeria, etc. also have our big rice plants.

My skype is violetyan99, whats app and mobile is +8613545045005, qq is 351599897,wechat is V13545045005. if you have any questions, please let me know.

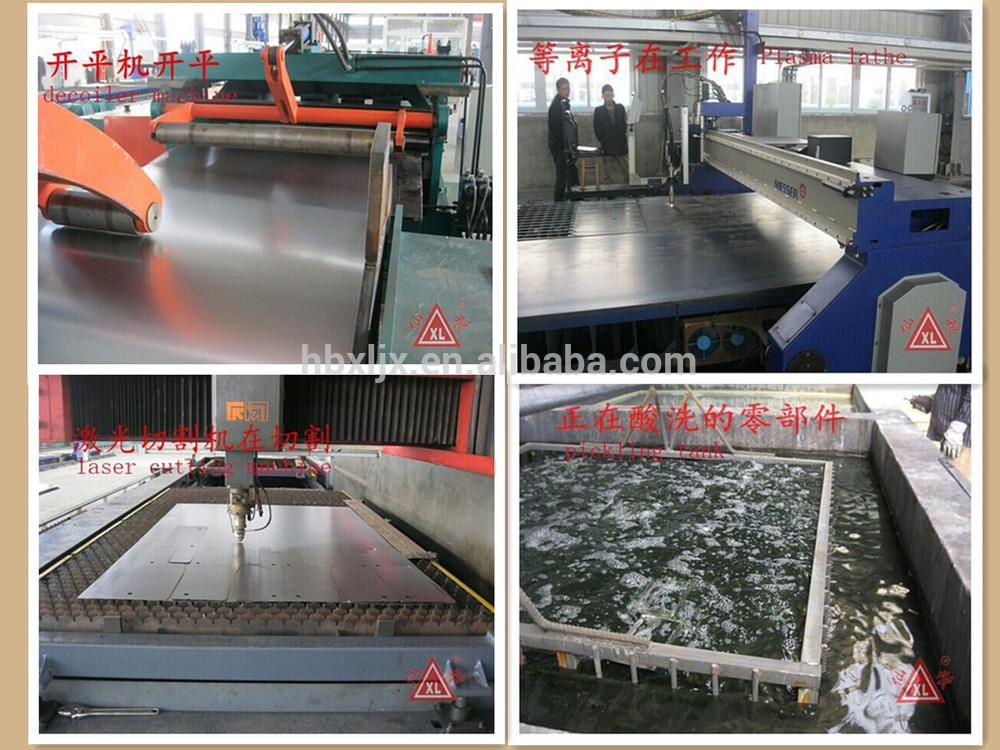

Hubei Xianliang Machinery Co., Ltd. is a professional agricultural processing machinery manufacturer. It was

established in 1990 and started to produce in 1991. Our company covers about 30000 square meters, and our annual production and sales amount reaches RMB40 million Yuan.

With almost ten years' research and development experience, our products won 21 National Patent, and our company has been identified as "High-tech enterprise".

Our products were listed in "catalogue of agricultural machinery products popularized by the state" in 2005 and became the agricultural machinery products supported and popularized by the state emphatically. We passed ISO9001:2000 international quality system certification in 2006 completely.

We are a grain machinery processing enterprise with perfect product quality, powerful technical strength and complete production equipment.

Dear friends, we are a professional rice machinery manufacturer with over 15 years experience. Our products won 21 national patents. Our company identify as high technology company. We have built some Rice Mill plants in foreign countries, with rich of experience. The dayout from 20-400T. Give us you target budget, we can give you the best combination.

Not ony big rice mill plant, also paddy dryer plant we can also provide to you. In Philippine, Senegal, Nigeria, Guyana,we have built some paddy dryer plant. The paddy dryer plant as below for your reference. If are interested , please kindly contact with me, Violet , my skype is violetyan99, whats app and mobile is +8613545045005,qq is 351599897,wechat is V13545045005. if you have any questions, please let me know.Thanks for your inquiry!

Dear friends, we are a professional rice machinery manufacturer with over 10 years experience. Our products won 21 national patents. Our company identify as high technology company. We have built some rice mill plants in foreign countries, with rich of experience. The dayout from 20-200T. Give us you target price, we can give you the best combination.

Choose us, no mistakes.

Welcome to visit our factory! More know, more trust.

Build a rice mill plant, not only products, but also combine, adjust, technical support, my skype is violetyan99, mobile and whats app is +8613545045005.qq is 351599897,wechat is V13545045005. if you have any questions, please let me know.

Contact us if you need more details on Rice Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Parboiled Rice Machines、Rice Plant. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Large Rice Mill Plant

Premium Related Products