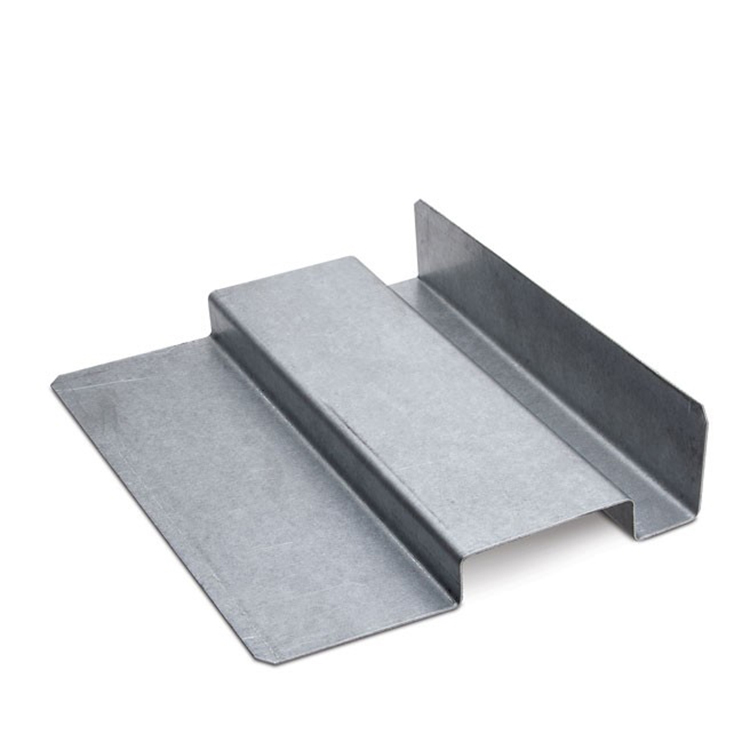

laser cutting bending parts

Product Description

1. Vaporization cutting: under the heating of the high power density laser beam, the surface temperature of the material rises to the boiling point temperature at a fast speed, enough to avoid the melting caused by heat conduction, so part of the material vaporizes into steam and disappears, and part of the material as ejecta is blown away from the bottom of the slit by the auxiliary gas flow.

2. Melting cutting: when the power density of the incident laser beam exceeds a certain value, the material at the irradiation point begins to evaporate, forming holes. Once the hole is formed, it absorbs all the energy of the incoming beam as a black body. The hole is surrounded by a wall of molten metal, and an auxiliary air stream coaxial with the beam carries away the molten material around the hole. As the workpiece moves, the hole moves horizontally synchronously in the cutting direction to form a slit. The laser beam continues to shine along the leading edge of the slit and the molten material is continuously or pulsating blown away from the slit.

3 oxidation melting cutting: melting cutting generally uses inert gas, if replaced by oxygen or other active gas, the material is lit under the irradiation of the laser beam, and oxygen occurs a fierce chemical reaction and produce another heat source, known as oxidation melting cutting.

Practical application and advantages of laser cutting machine in sheet metal processing:

1) Laser cutting can effectively use the advantages of programming software, greatly improve the utilization rate of thin plate materials, reduce the use and waste of materials, and reduce the labor intensity and strength of workers, to achieve the ideal effect. On the other hand, the optimization of the function of the discharge can omit the opening link of thin plate cutting, effectively reduce the material clamping, reduce the processing auxiliary time. Therefore, promote the cutting scheme more reasonable arrangement, effectively improve the processing efficiency and material saving;

2) In the increasingly developing market environment, the speed of product development means market. The application of laser cutting machines can effectively reduce the number of molds used, save the development cycle of new products, and promote the speed and pace of their development. Parts after laser cutting, the quality is good, and obviously, increase the production efficiency, help to small batch production, powerful guarantee the market atmosphere of the product development cycle is shortened, and the application of laser cutting, the size of the blanking die can be precise positioning, for future mass production beds down-solid basis;

3) in the sheet metal processing work, almost all need laser cutting machine in the last panel forming operation, and directly welded joint sets, so the application of laser cutting machine to reduce the working procedure and the time limit for a project, effectively improve the work efficiency, can realize the workers labor intensity and dual optimization and reduce processing costs, promote the optimization of the work environment at the same time, Greatly improve the speed and progress of research and development, reduce mold investment, effectively reduce the cost;

4) The widespread application of laser cutting machines in sheet metal processing can effectively shorten the processing and manufacturing cycle of new products, greatly reduce the investment of mold, etc.; Greatly improve the processing speed of workers, eliminating unnecessary processing procedures; At the same time, the laser cutting machine is widely used in industrial processing, can effectively process a variety of complex parts, improve accuracy, help directly shorten the processing cycle, improve the accuracy of processing, omit the stamping die replacement procedures, effectively improve labor productivity.

Product Categories : Laser Cutting